BBST

BSST Team | ZWU

2024.6

3D printing, also known as stereoscopic printing or additive manufacturing,

is a technology that manufactures physical parts based on 3D CAD data

through the method of layer-by-layer material accumulation. The core

principle of this technique is to add materials layer by layer, transforming

the digital design into a physical object.

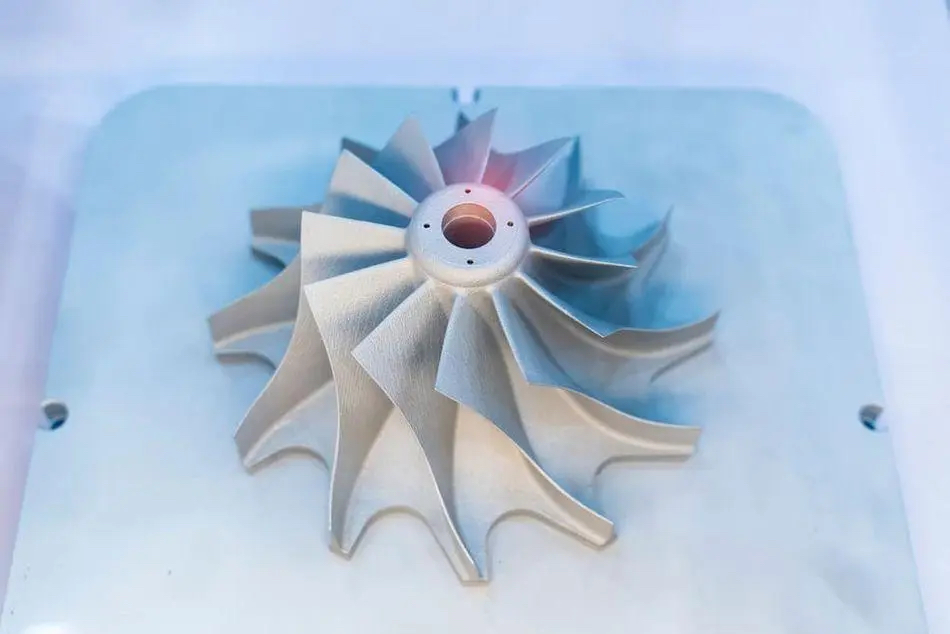

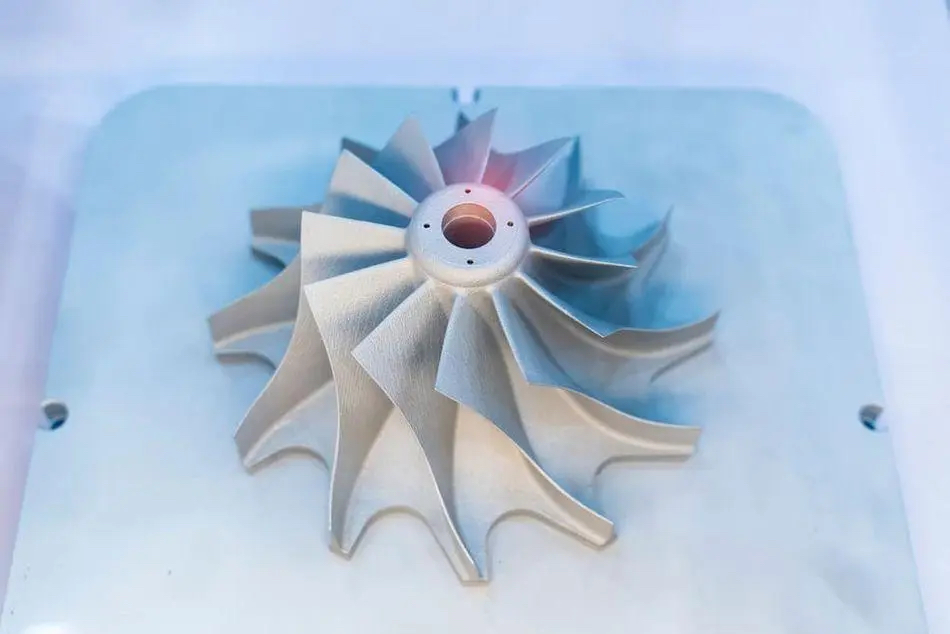

The Selective Laser Sintering (SLS) process was first proposed by

American Carl Deckard in 1989, and DTM Company launched the commercial

production equipment for this process in 1992.

Current research status of SLS technology:

DTM Company and 3D Systems Company in the United States, EOS Company in

Germany; Domestic companies such as Beijing Longyuan Automatic Forming

System Co., Ltd. and Huazhong University of Science and Technology. At

present, significant achievements have been made in RP molding systems,

SLS molding machines, metal powder research, sintering theory, scanning

paths, and other areas in China.

1.3D printer background

2.new application, new technology about material,machine,new paper

3.SLS 3D Printing

4.

Advantages and disadvantages of SLS process

Course → 3D Printing

https://mo.mbd.baidu.com/r/1lrqLZVTyqQ?f=cp&rs=3686669284&ruk=nkomwqMWdZ5oHqM2DexJvg&u=2700e6c310f8f402

Advantage:

-

Diversity of molding materials and low cost. This is the most prominent

feature of SLS. In theory, materials that can form atomic connections

between powders after laser heating can be used as SLS forming

materials. At present, commercialized materials mainly include plastic

powder, wax powder, coated metal powder, ceramic powder coated with

adhesive on the surface, coated sand, etc.

-

There are almost no requirements for the shape of the parts. Due to the

fact that the powder in the lower layer naturally becomes the support

for the upper layer, SLS has self-supporting properties and can

manufacture any complex shape, which many RP technologies do not

possess. Forming is not limited by the inability of traditional

machining tools to reach certain surfaces.

- High material utilization rate. Unsintered powder can be reused.

-

The parts have good mechanical properties. The finished product can be

directly used for functional testing or small batch use.

-

Realize integrated design and manufacturing. The supporting software can

automatically convert CAD data into layered STL data, generate CNC codes

based on layer information, and drive the forming machine to complete

layer by layer processing and stacking of materials without human

intervention.

- The equipment cost is high.

-

The interior of the product is loose and porous, with high surface

roughness and low mechanical properties.

-

The quality of the parts is greatly affected by the powder, making it

difficult to improve.

- The maximum size of parts that can be manufactured is limited.

-

The molding process consumes a lot of energy and the post-processing

process is complex.

Disadvantage:

Materials:

There are many materials for 3D printing, including plastics, metals,

ceramics, gypsum, and even biomaterials. Which material you choose

depends on the functional and performance needs of the object you are

printing on. For example, plastics are commonly used to print models and

prototypes, while metals are often used to print structural parts.

Machines:

There are many types of 3D printers, including fused deposition modeling

(FDM) printers, stereolithography (SLA) printers, selective laser

sintering (SLS) printers, etc. Different types of printers are suitable

for different applications, such as FDM printers are often used to print

plastic parts, and SLS printers are often used to print metal parts.

New applications:

With the development of 3D printing technology, its application fields

are also expanding. For example, in the medical field, customized

prosthetics and medical devices can be printed; In the field of

construction, complex building components can be printed; In the field

of art, it is possible to print beautiful works of art.

New technologies:

3D printing technology is also constantly evolving and innovating. For

example, 4D printing is an emerging technology that can print objects

that change shape over time. In addition, multi-material 3D printing is

also a research hotspot, which can print multiple materials in the same

object to achieve more complex functions and properties.

Refrence:

http://pfxbzlx.gdvdc.com/CN/10.3969/j.issn.1674-8468.2023.04.014

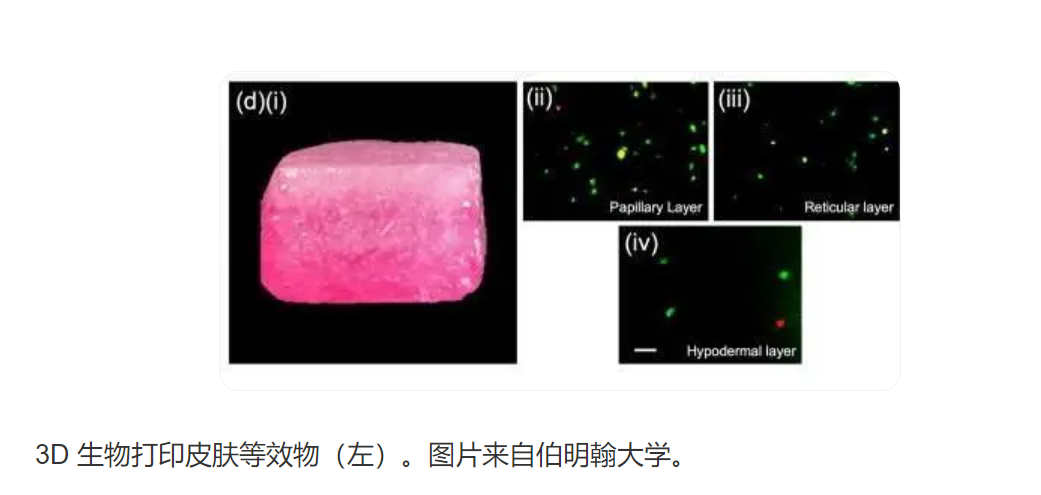

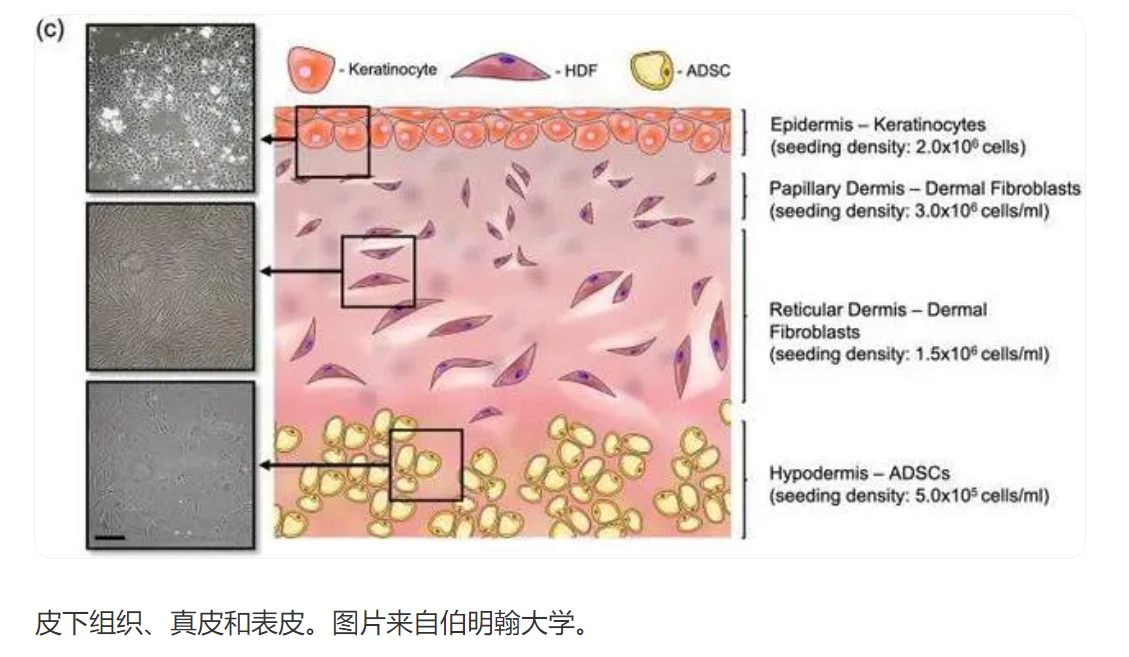

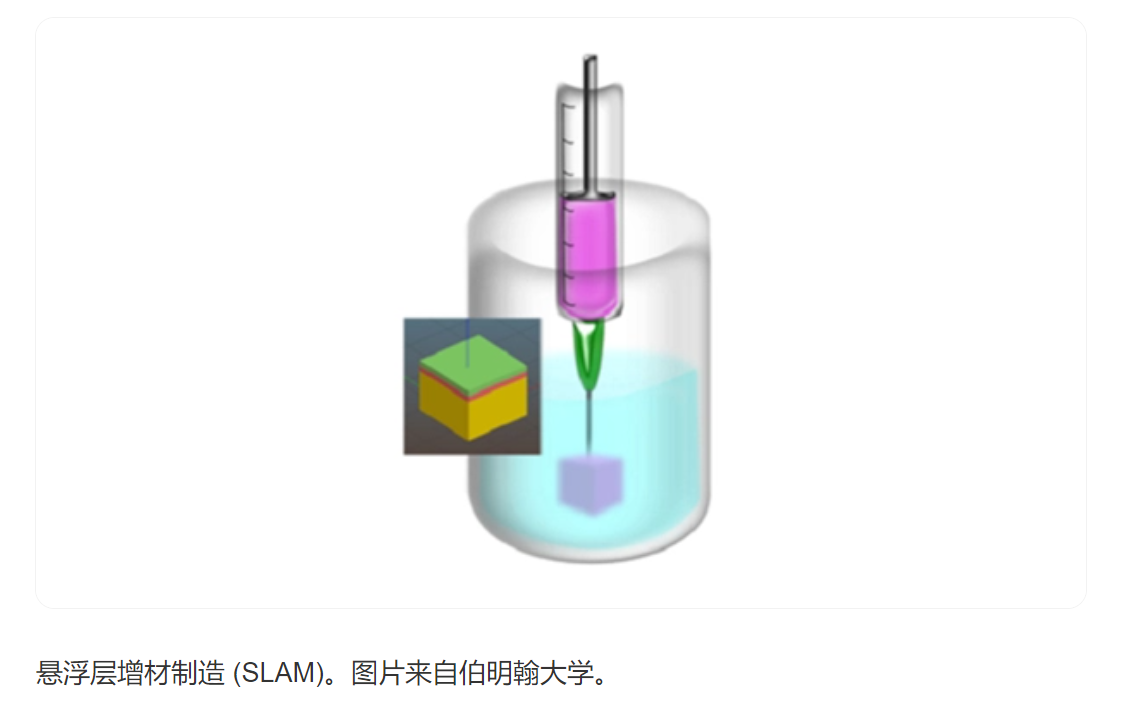

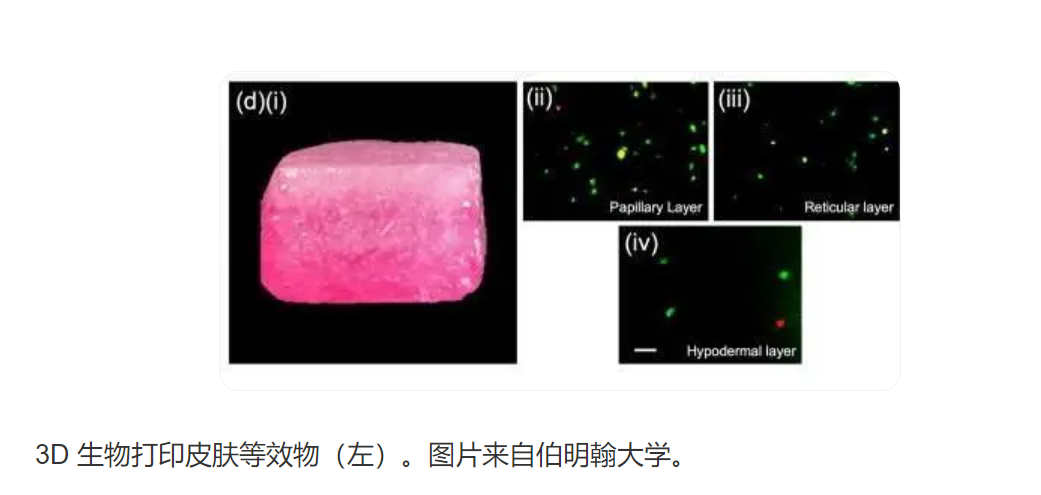

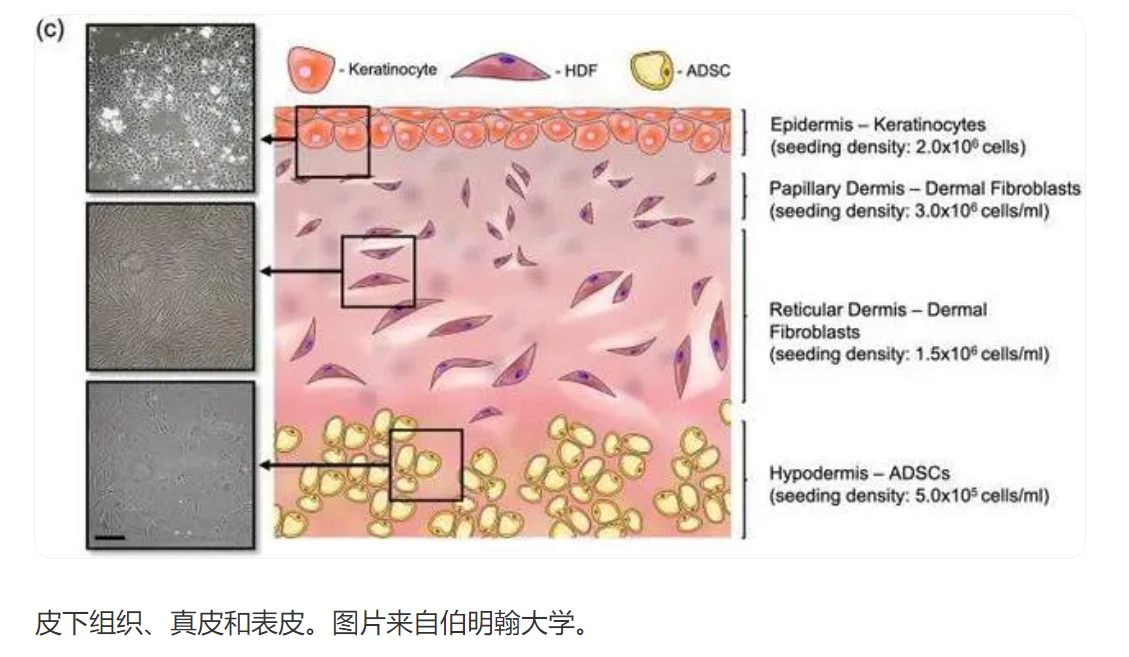

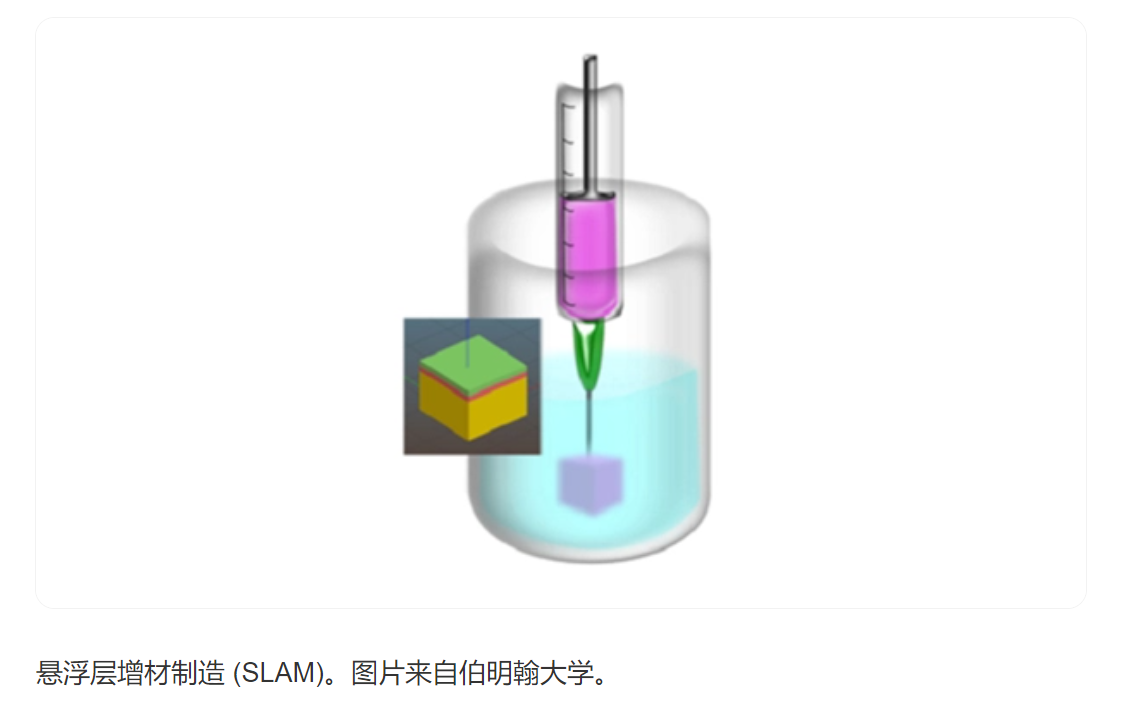

printing has significant application potential in the field of skin

repair. Researchers can maximize skin activity and other natural

properties by integrating different extracellular matrices into skin 3D

printing technology, thereby achieving effective repair of damaged skin

and fusion with normal skin. In addition, for patients with severe skin

burns caused by fires, 3D printing technology can quickly and accurately

print materials containing skin cells, construct biomimetic skin

structures, thereby shortening the treatment cycle and reducing

postoperative scars.

Application of in situ skin bioprinting

-

In situ skin bioprinting utilizes inkjet bioprinting technology, which

uses handheld devices or robot automation systems to directly print

cell filled bioprinting onto the human wound site [6]. This

bioprinting method can print concentrated skin cell suspensions onto

wounds to accelerate their healing. Hakimi et al. [14] developed a

handheld 3D in situ bioprinter that can be directly printed in mouse

and pig wound models, with cells forming skin patches in situ on the

wound. Albanna et al. [6] used portable inkjet bioprinters and laser

bioprinters to print high-density suspensions of human fibroblasts and

keratinocytes onto full-thickness skin excised wounds in experimental

mice using fibrin collagen bioprinters. The skin structure printed on

the wound retains a high cell density, and for up to 6 weeks after

printing, human cells can also be observed in the tissue. Compared to

untreated and cell-free grafts, direct in situ skin 3D bioprinting

therapy leads to faster wound healing.

-

Skardal et al. [7] also evaluated the role of stem cell-derived seed

cells in wound healing by using a robotic inkjet bioprinter to

directly print amniotic fluid derived stem cells (AFSC) and fibrin

collagen bioprinters carrying bone marrow mesenchymal stem cells

(BM-MSCs) onto the wounds of mice undergoing full layer skin

resection. Compared with the pure gel control group, the mice treated

with AFSCs and BM MSCs had faster wound closure and epidermal

formation. In another experiment to regulate paracrine activity at the

wound site, Skardal et al. [7] printed heparin coupled hyaluronic acid

hydrogel containing AFSCs directly on the wound of full-thickness skin

resection. The hydrogel can isolate the cytokines secreted by AFSC in

situ, extend paracrine activity, and make the full-thickness wound

faster closed and vascularized. The main advantage of in situ

bioprinting is the ability to layer cell ink based on the precise

shape of the wound, making it particularly suitable for treating

irregularly

5.find new reseach or application

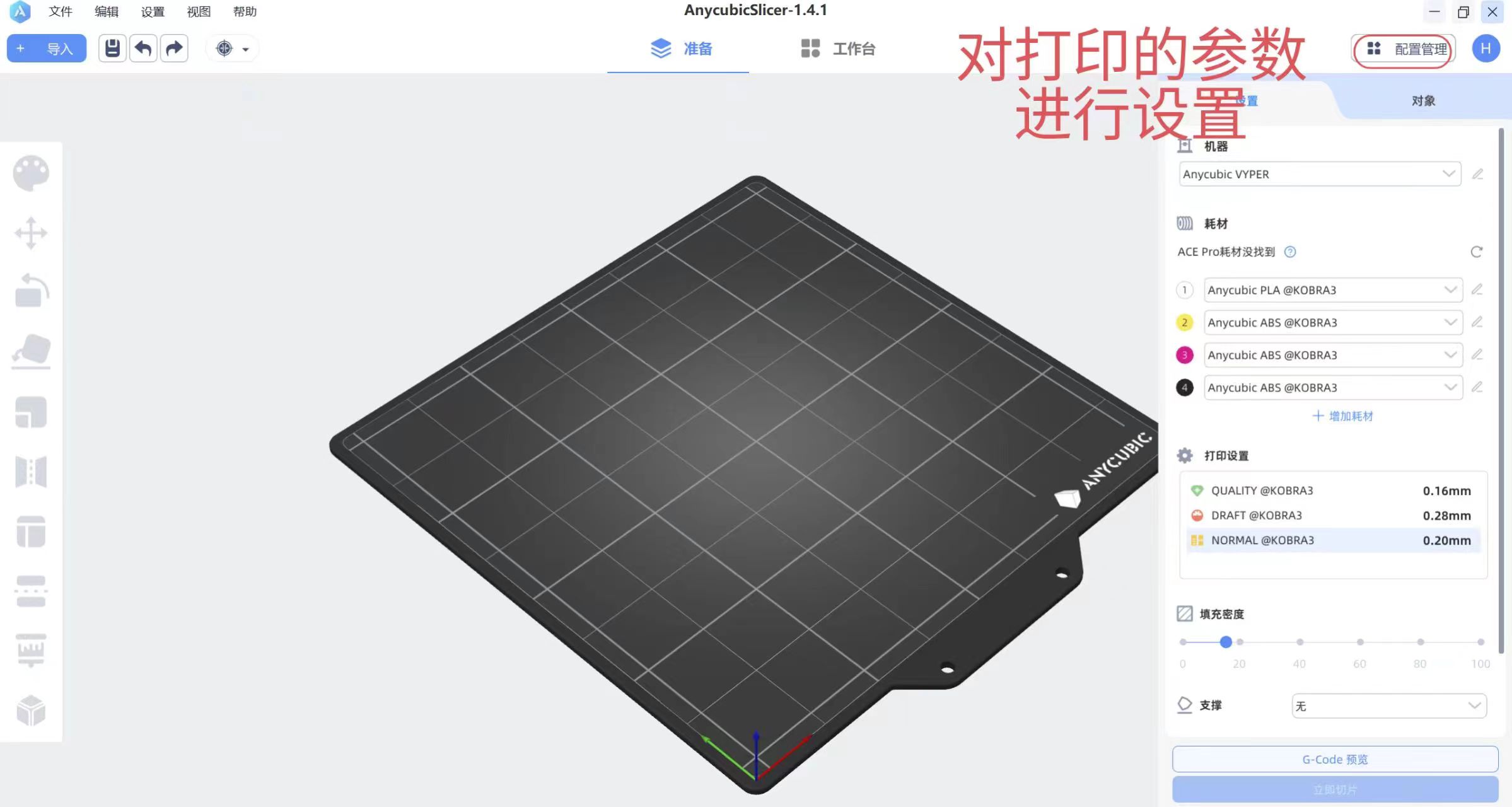

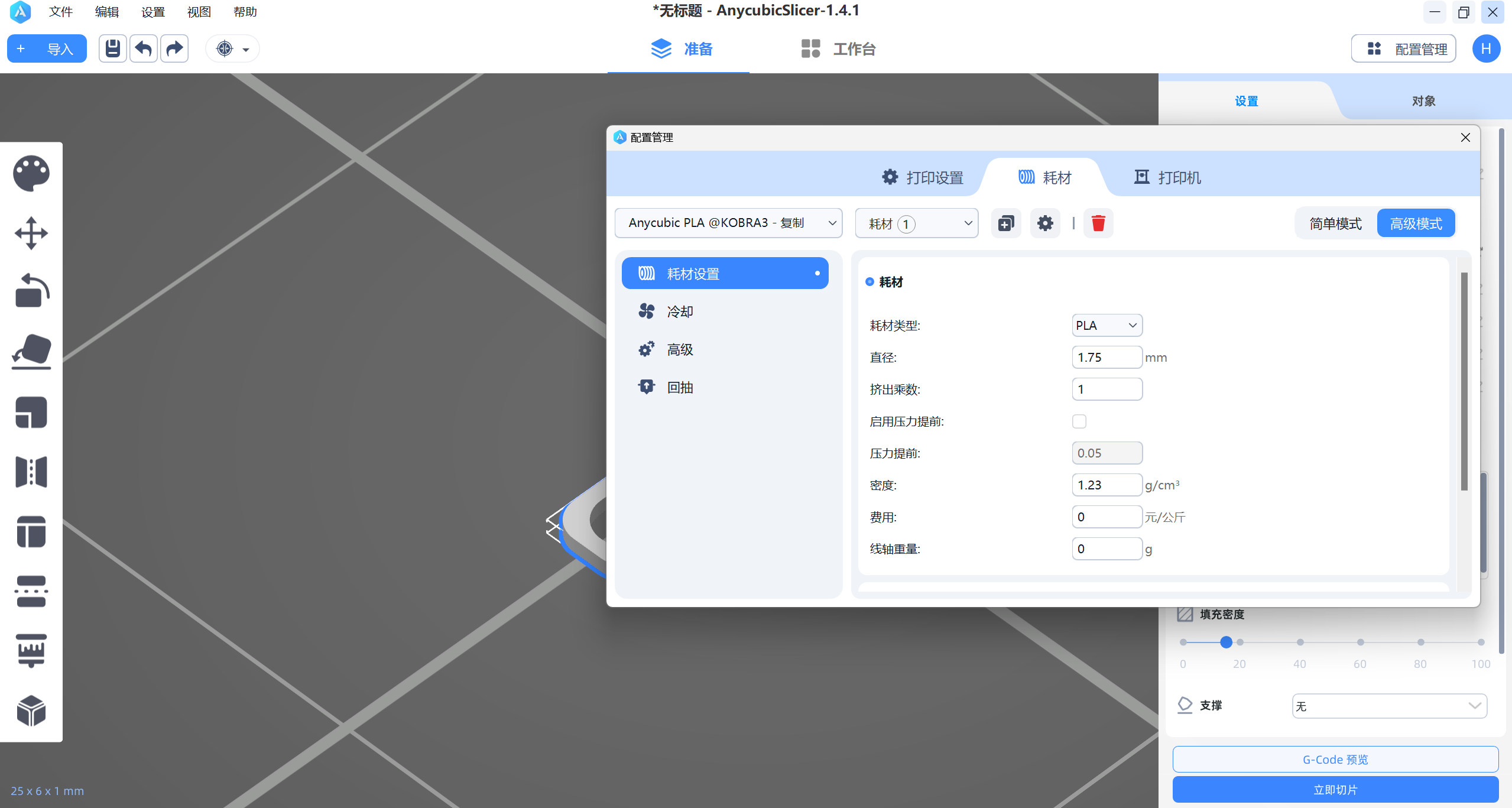

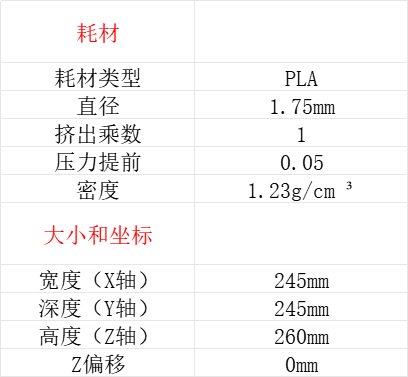

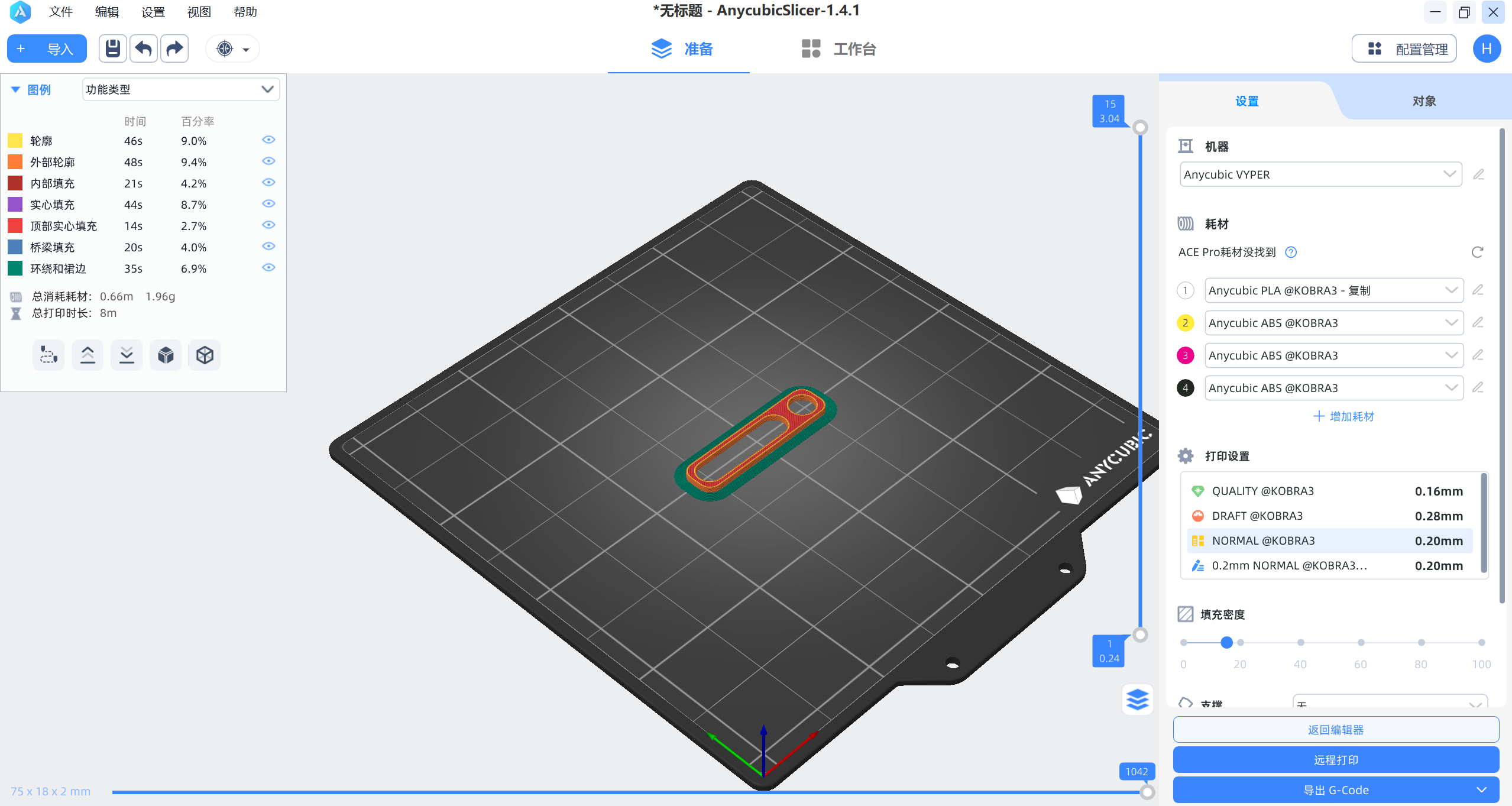

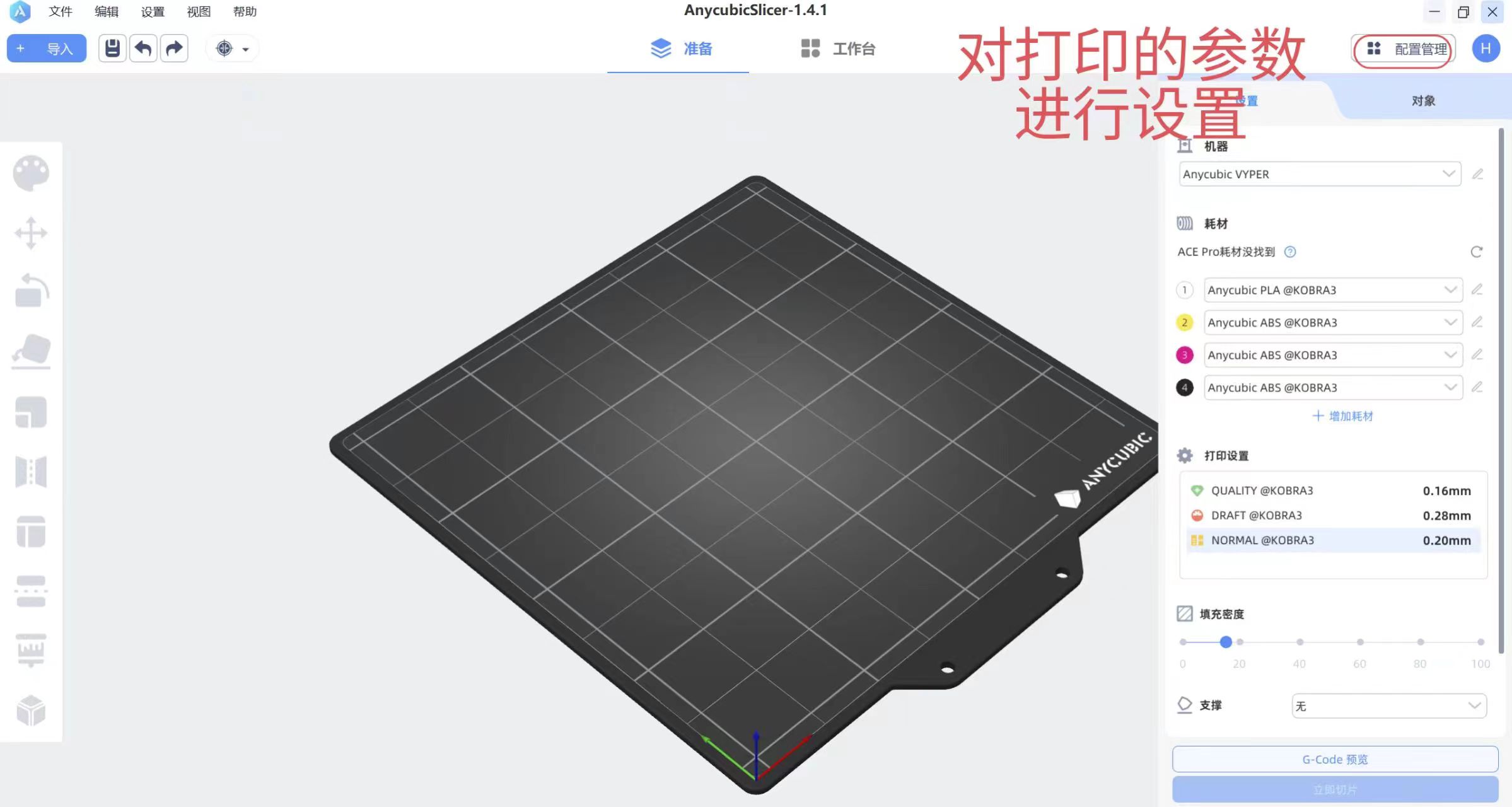

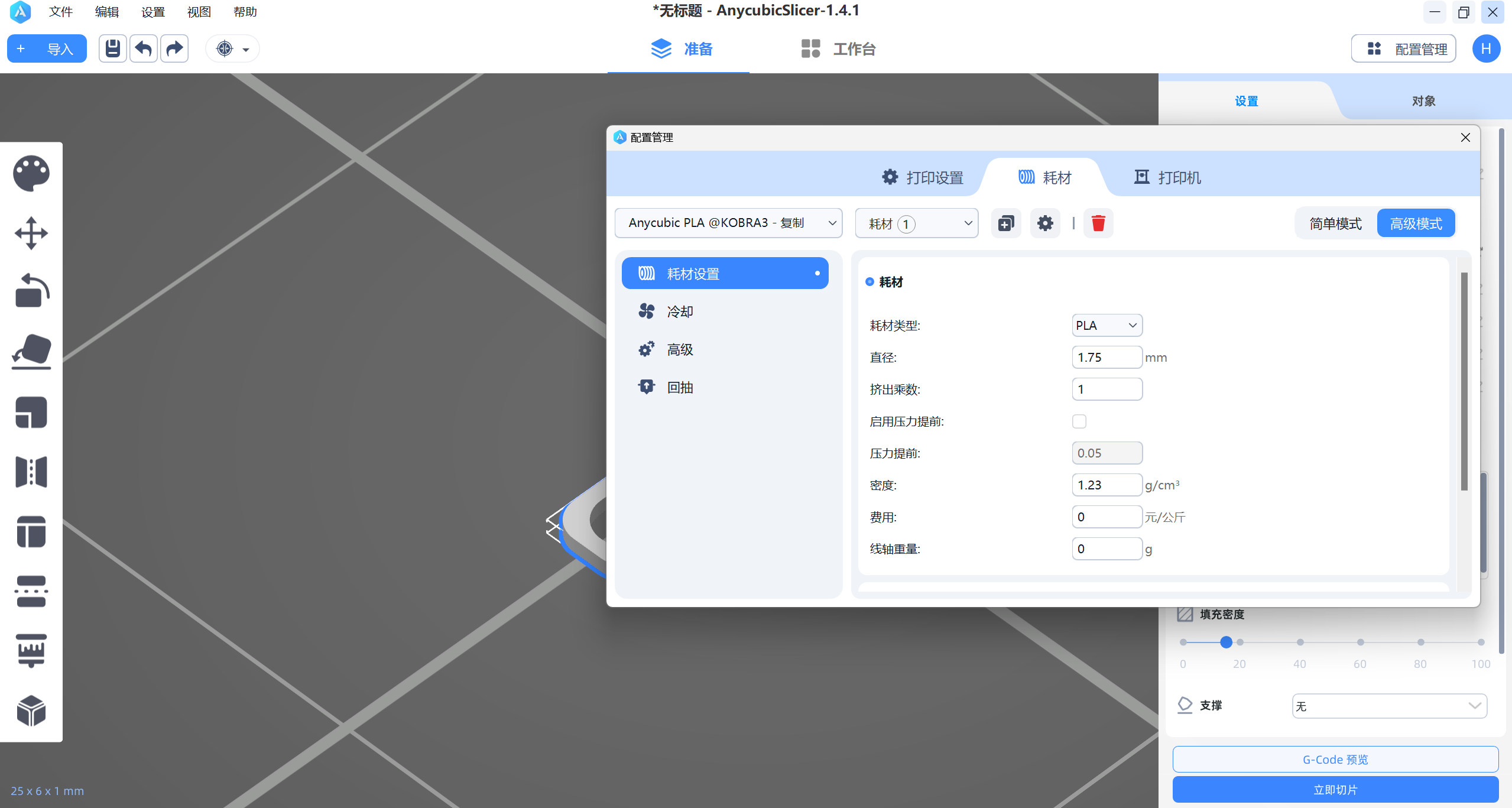

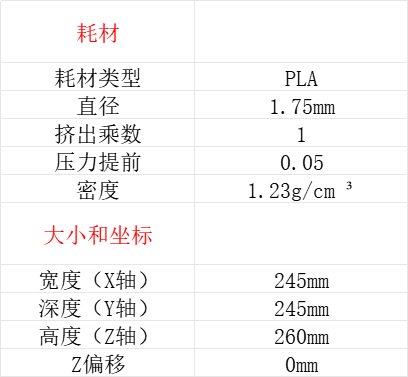

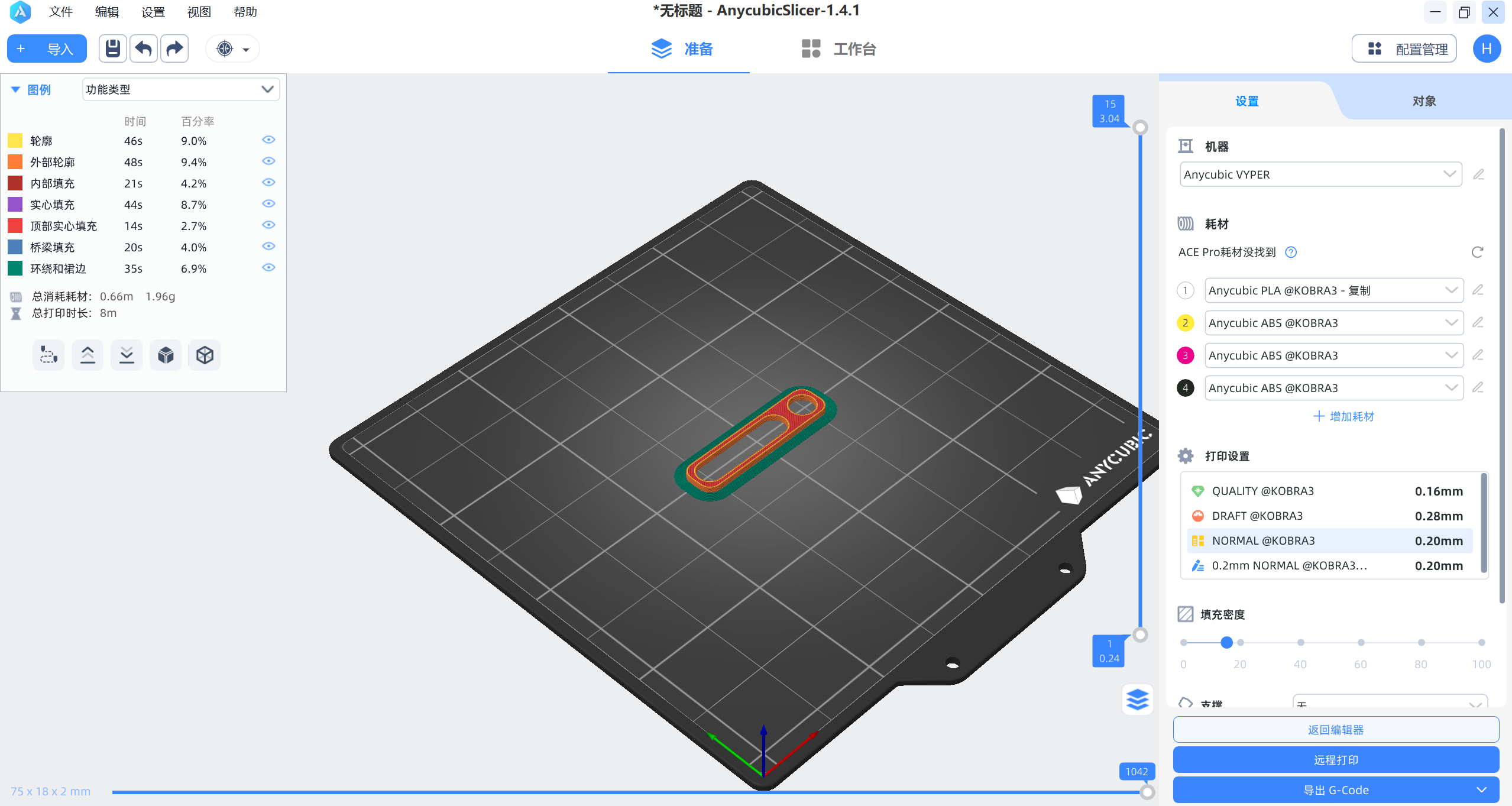

6.Use slice software to setting parameter

Use the tools on the left to sketch.

Constrain sketches through "sketch dimensions" and the right

toolbar.

The sketch line before constraint is blue, and the sketch line after

constraint is black.

Parts can be constrained by labelling the size.The shortcut key is

CapsLK plus D.

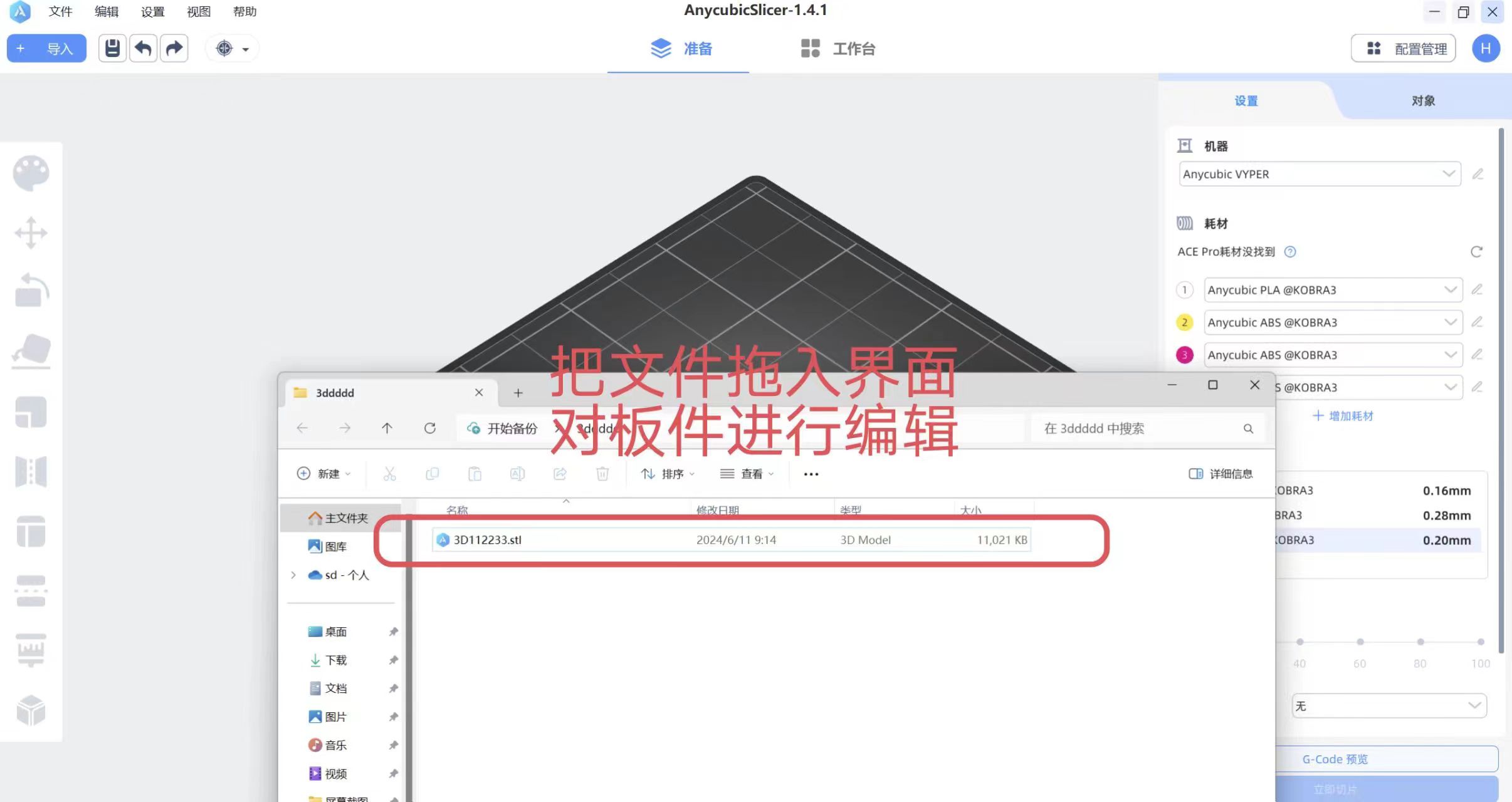

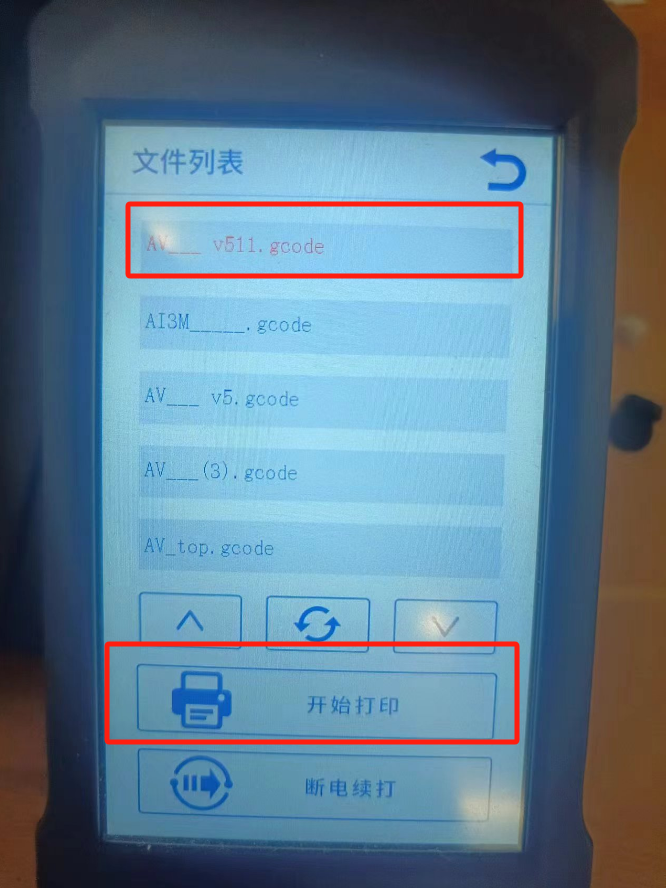

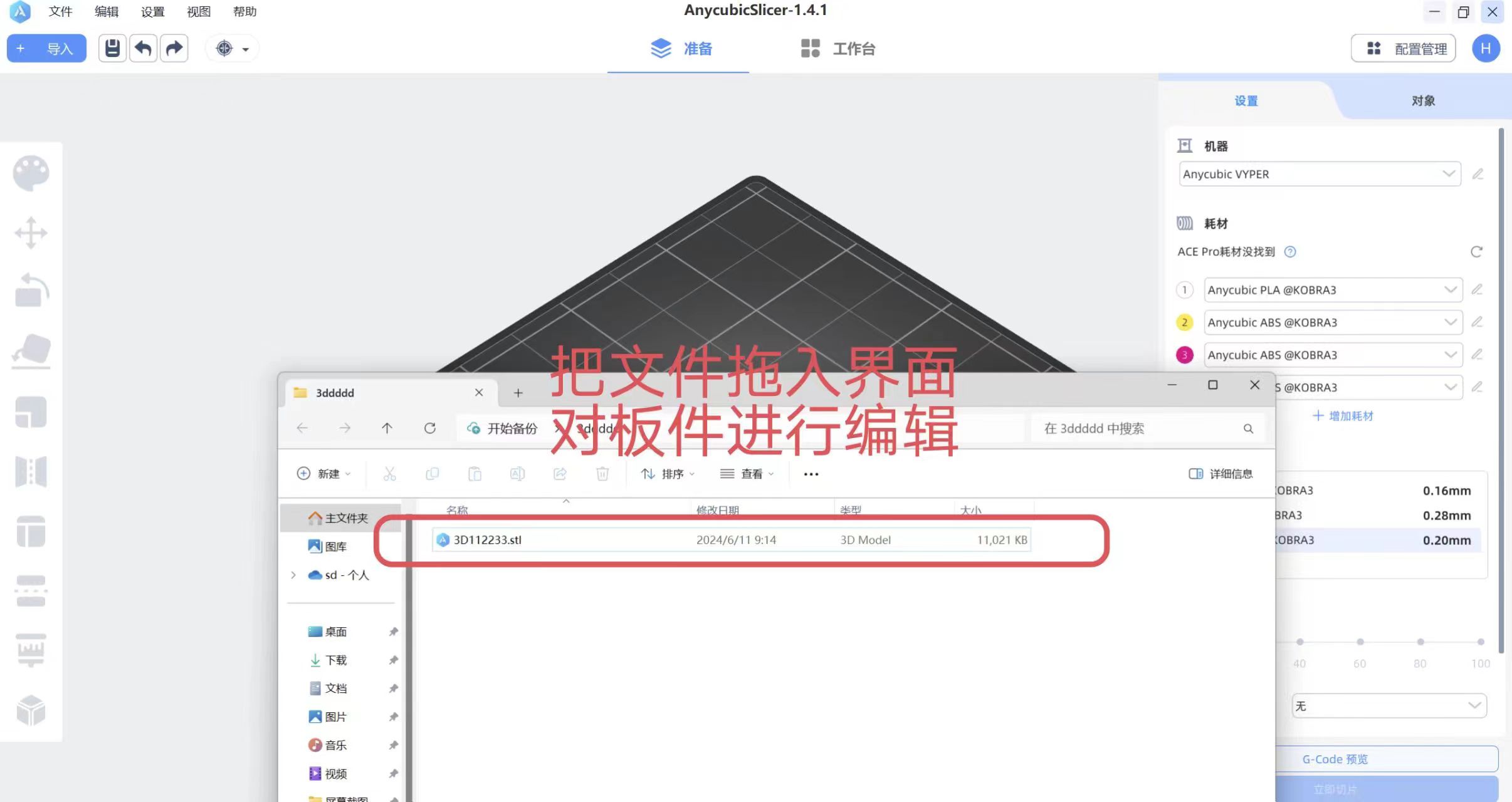

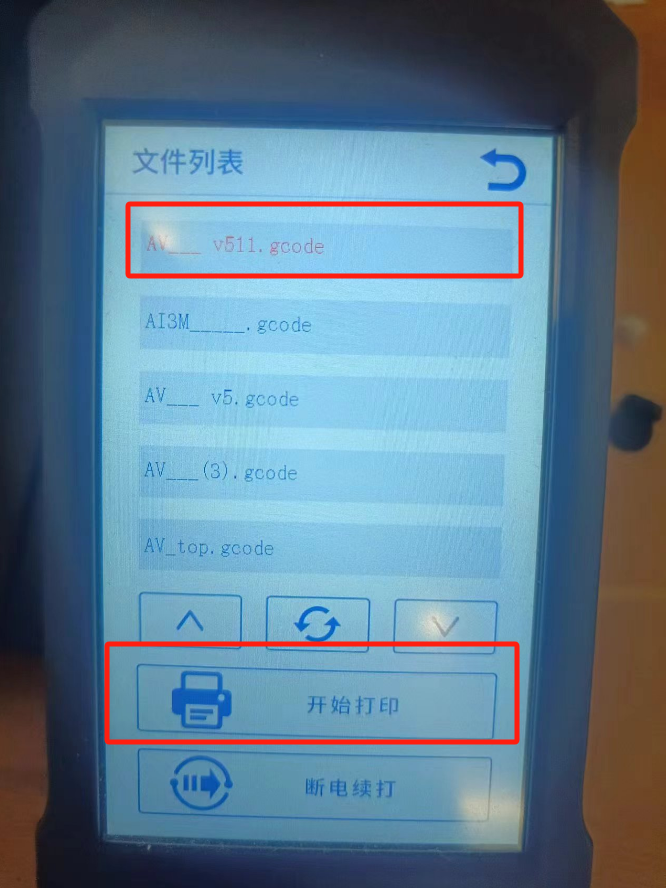

7.Use 3D printer to manufacture it

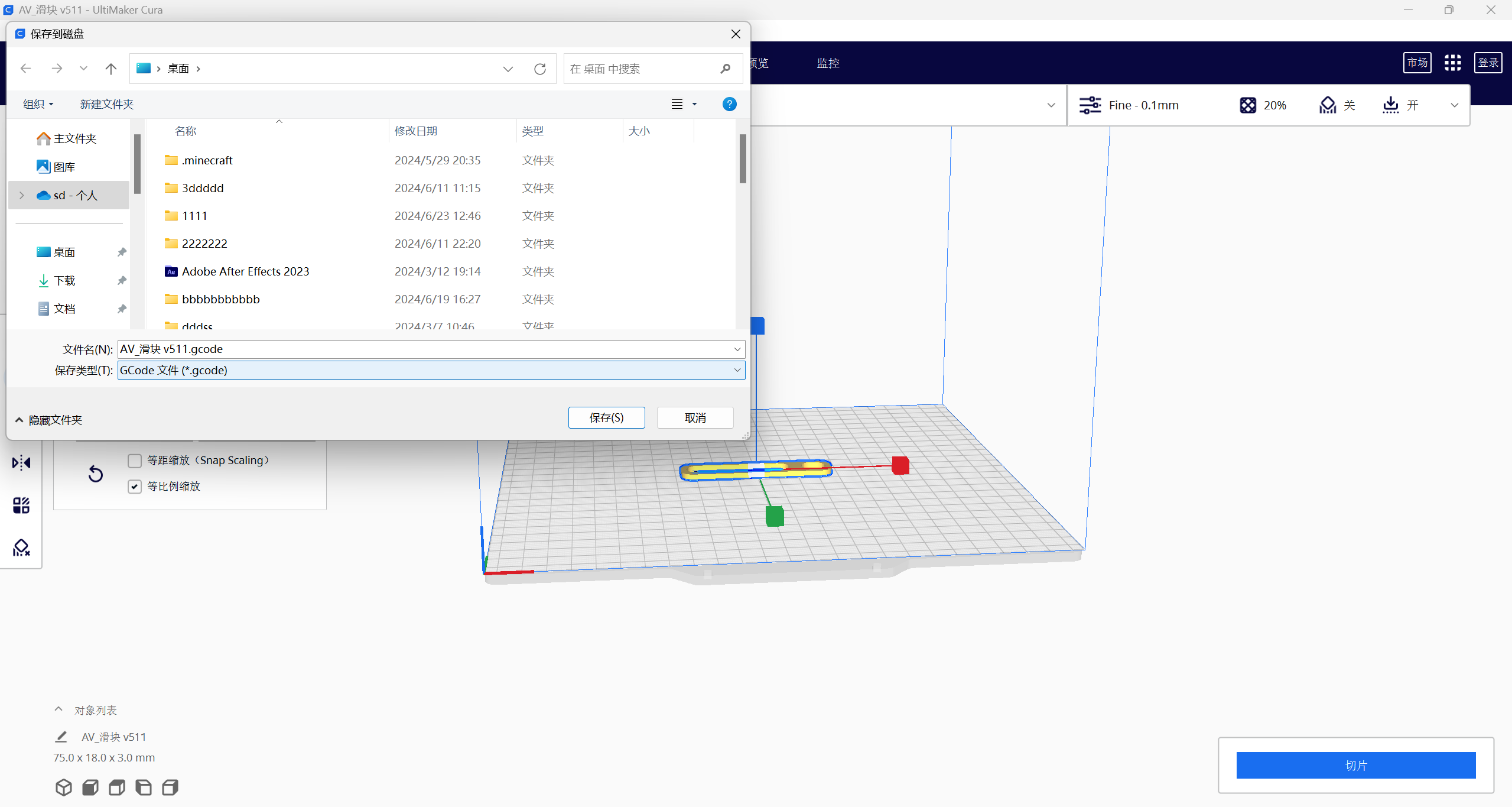

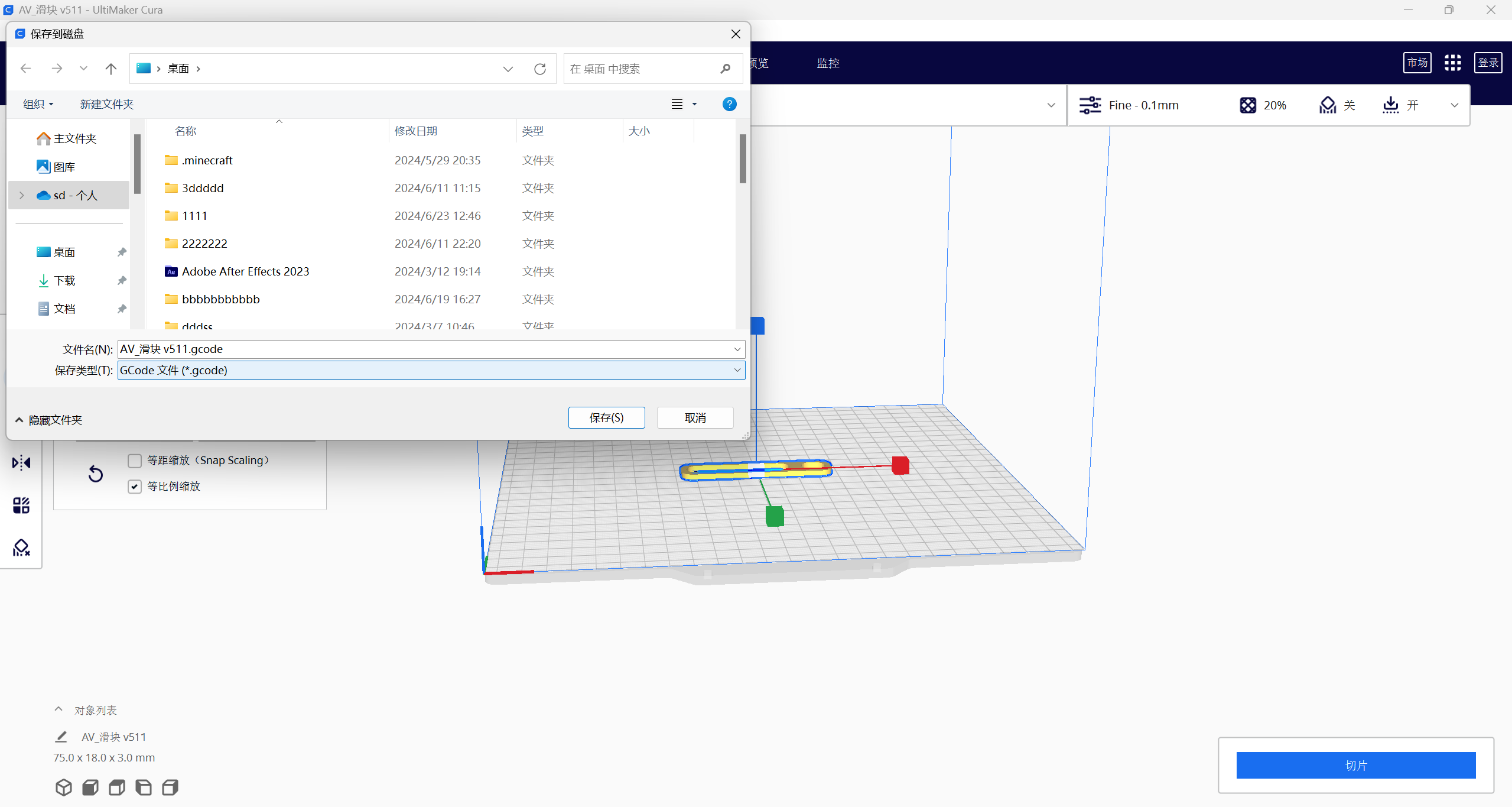

1.Drag the exported stl of Anycubic Slicer after modifying parameters into

UltiMaker Cura.

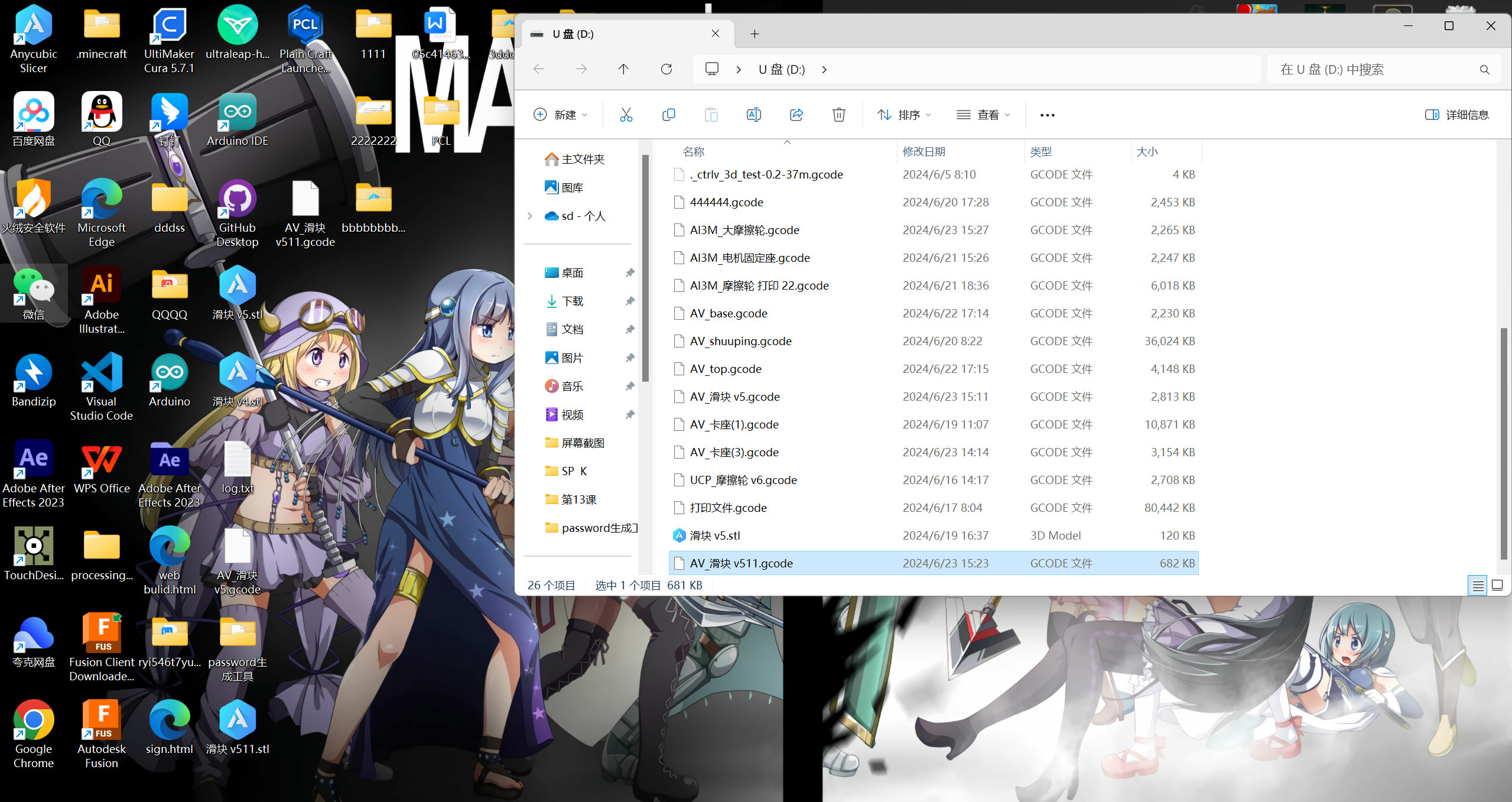

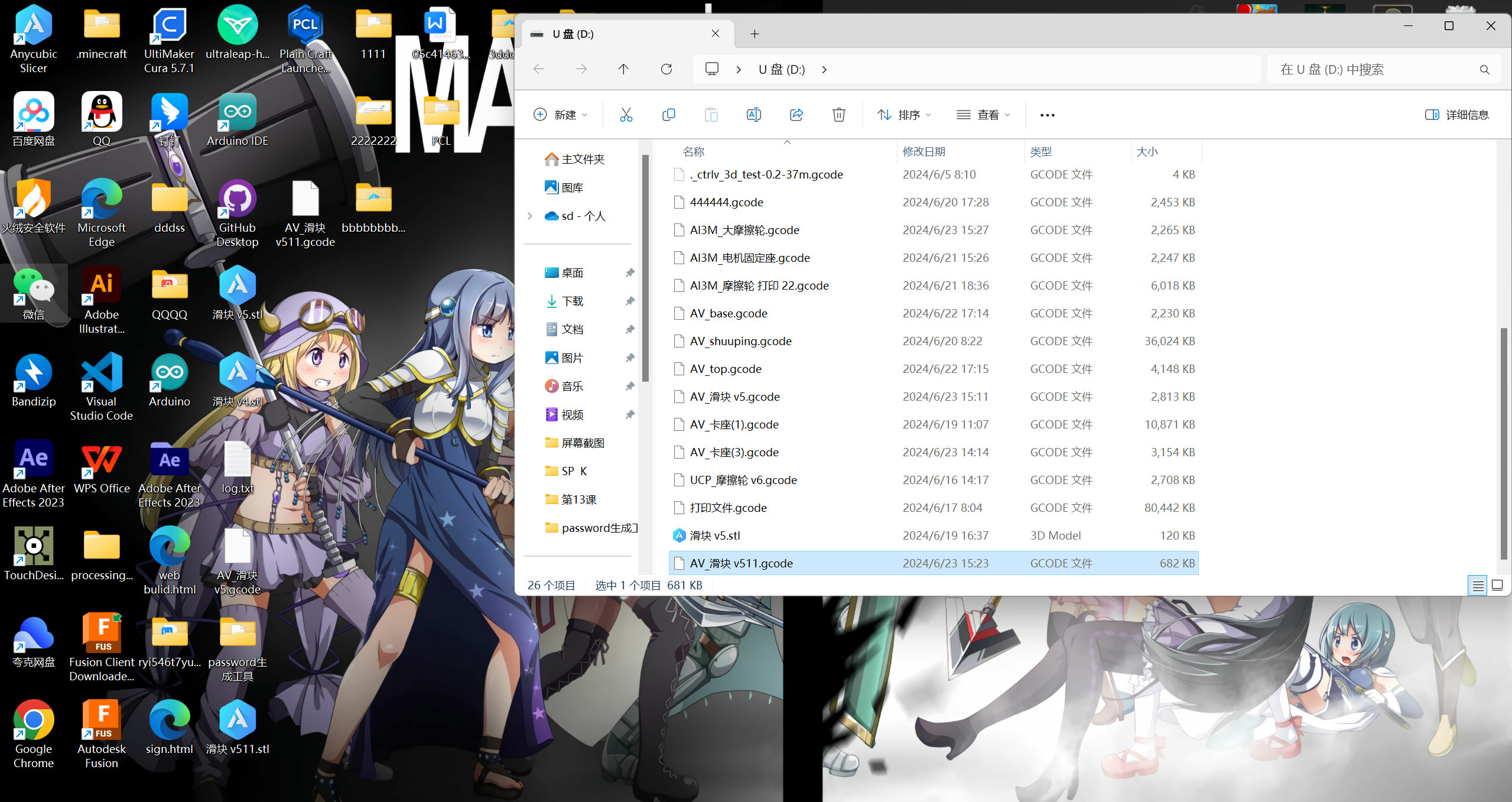

2.Export as gcode after slicing

3. Drag the gcode file into the USB drive.

4.Insert the USB drive into the 3D printer

5. Find the file (

the latest file is usually in the first place

) and start printing

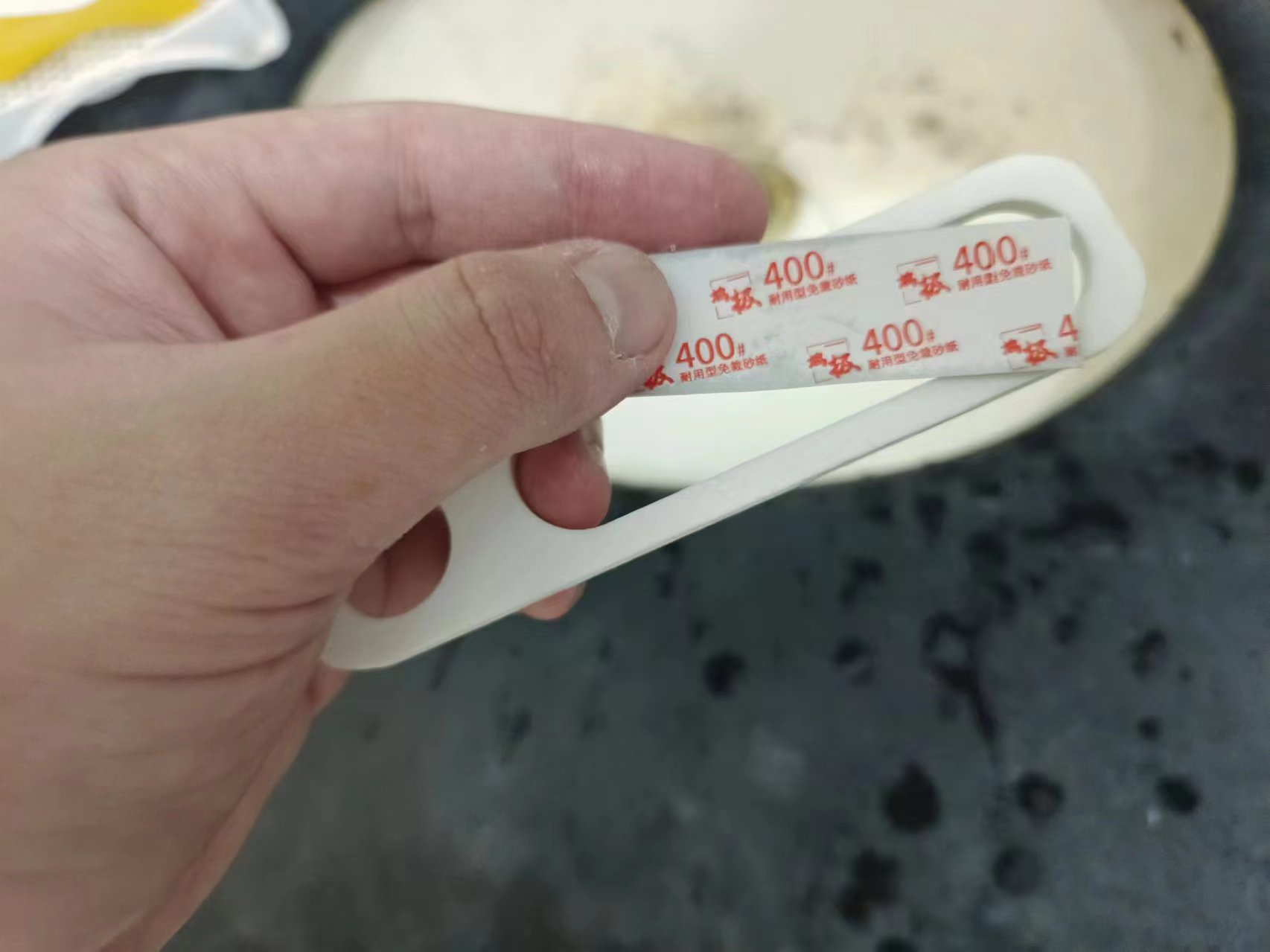

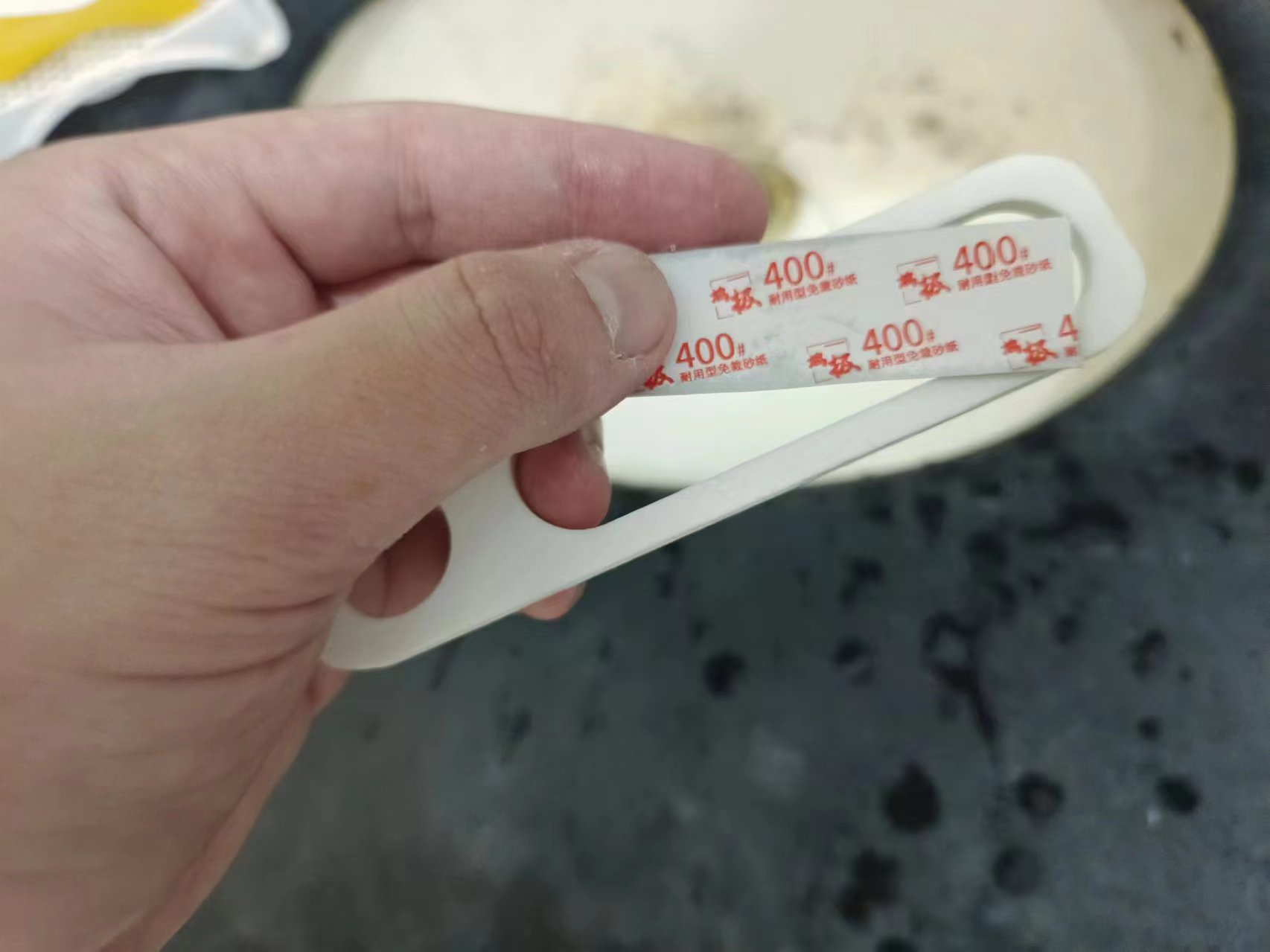

2.Sandpaper soaked in wet and polished

400-eye rough repair of the muse

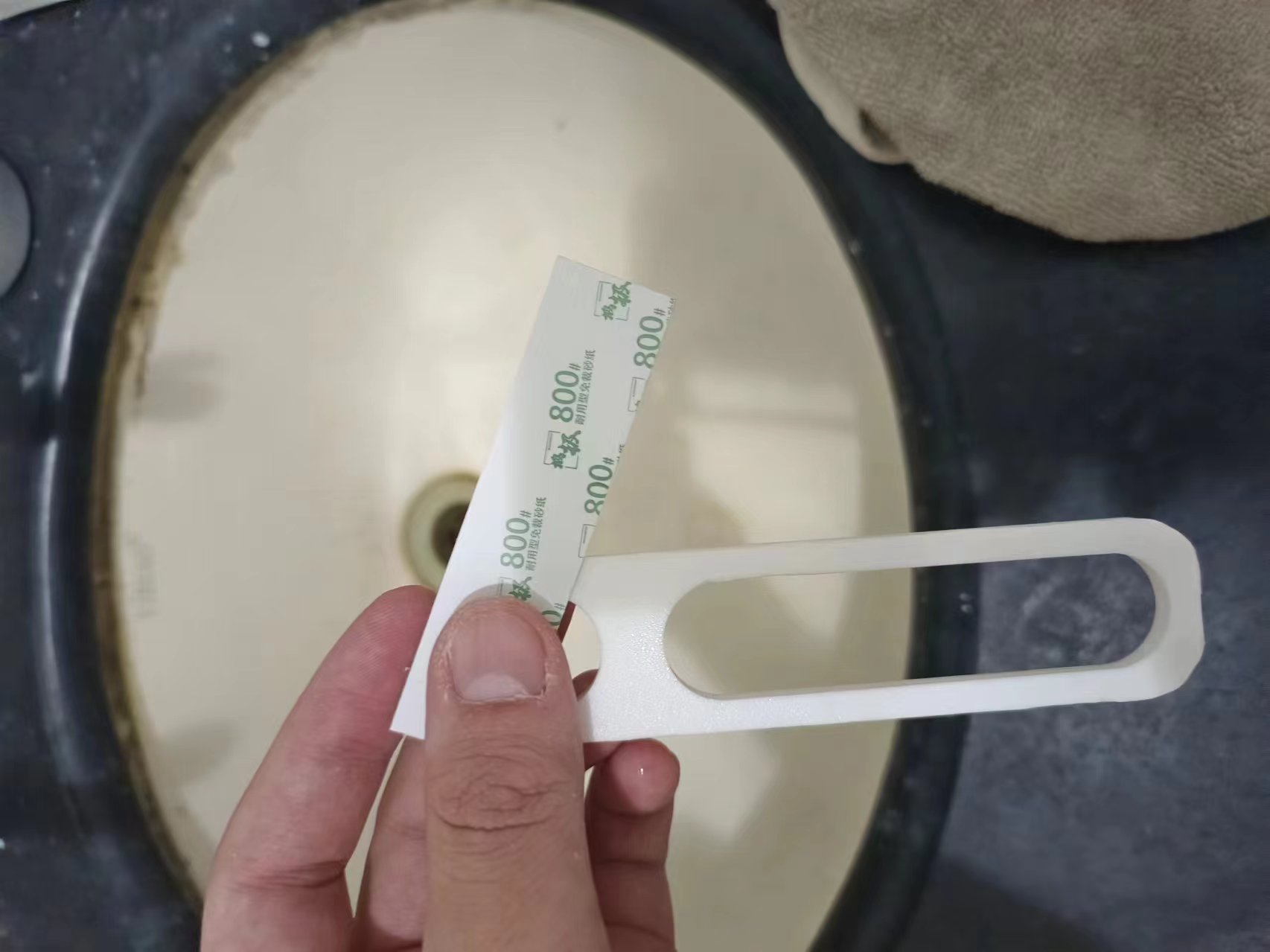

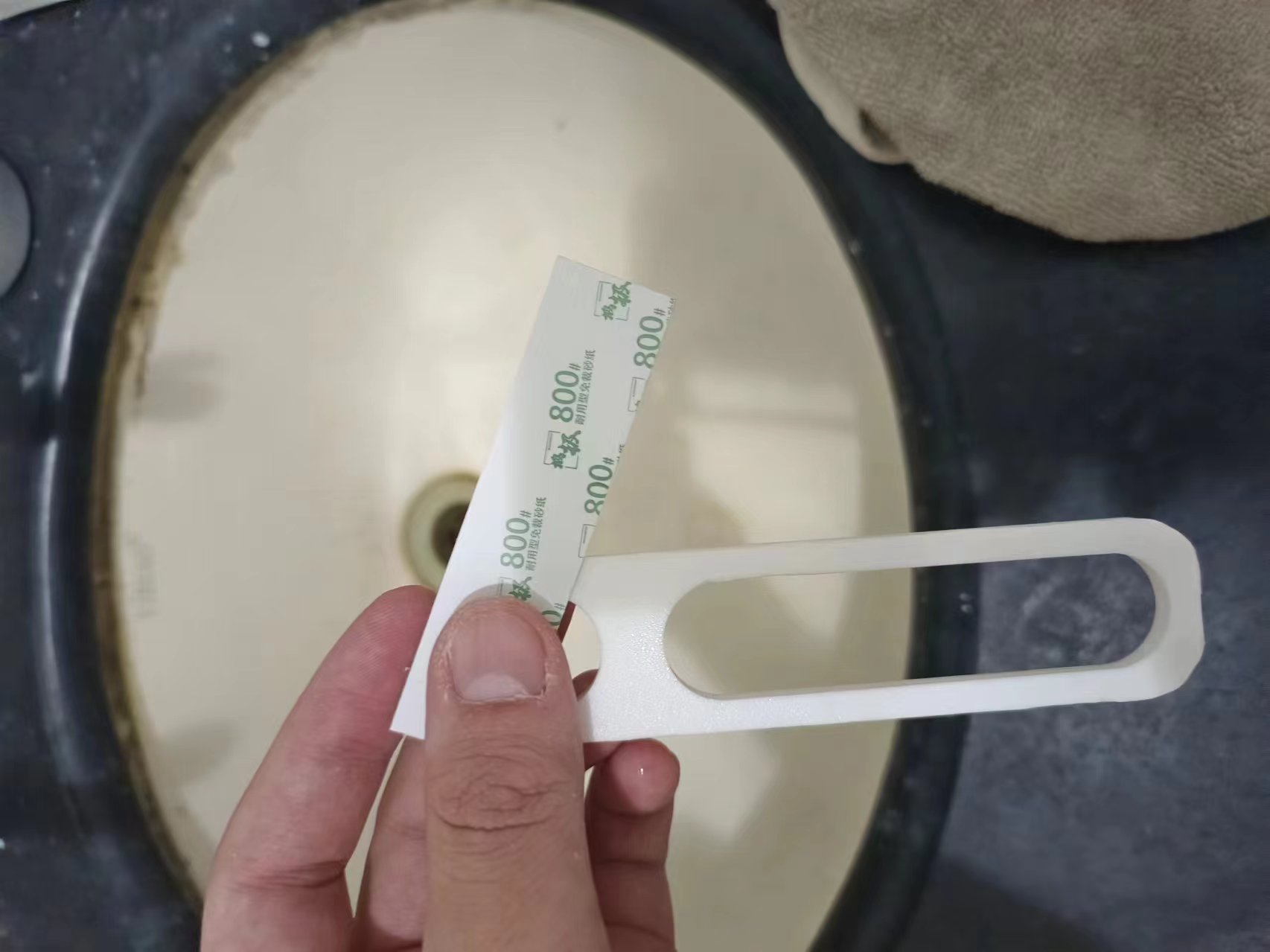

3.800 mesh refinement

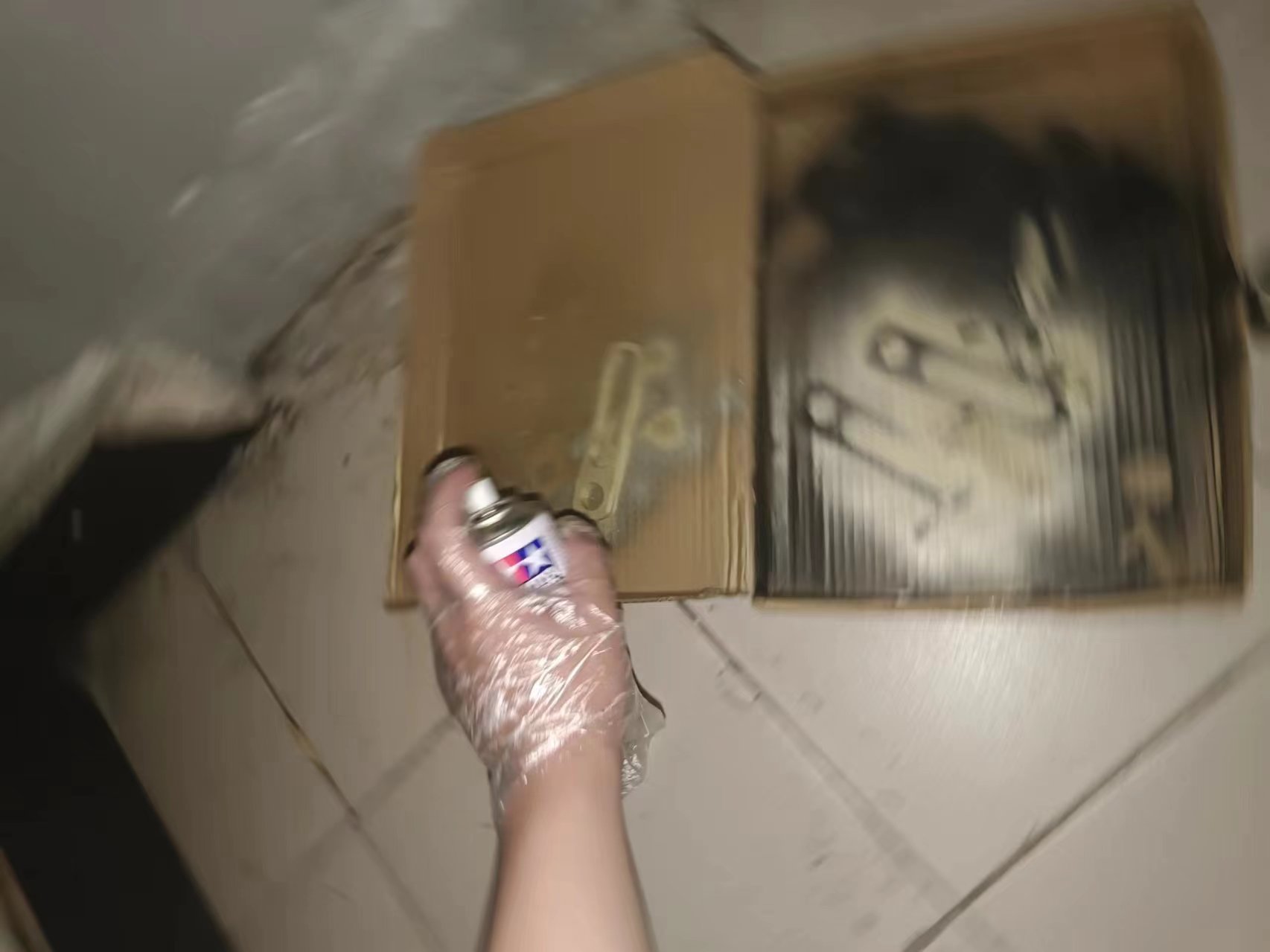

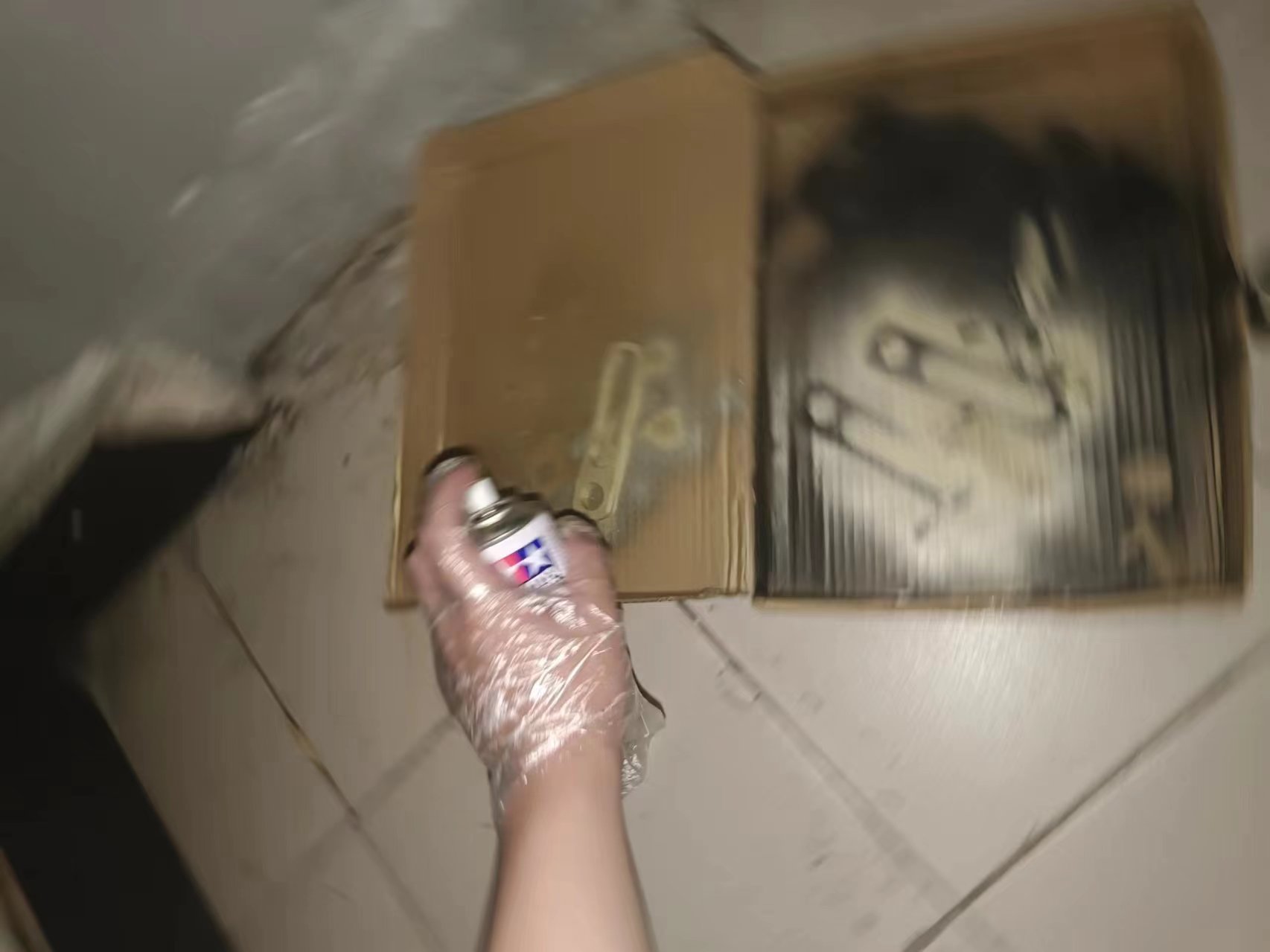

4.Surface painting of gas masks and spray cans

5.Shake and spray paint twice in 15 minutes and finally dry

8.Postprocess the surface

1.Pliers: Remove the support and skirt

Slickets and sandpaper: polishing